With the approach of winter, it is again time to remember cold weather concreting practices. ACI 306R now defines cold weather as any time the air temperature falls below or is expected to fall below 40°F during the protection period, or the period required to prevent the concrete from being adversely affected by exposure to cold weather.

Cold weather affects concrete in many ways. For one, hydration in concrete, the process of gaining strength, is a chemical reaction. When concrete is placed at colder temperatures, hydration can be slowed 2 and even stop 2 impacting finishing and curing times. Another concern is the permanent damage that concrete may experience if it is allowed to freeze at an early age.

Construction Practices

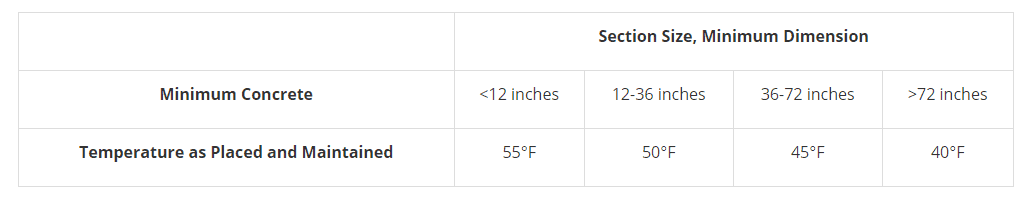

The American Concrete Institute (ACI) has developed the following chart. It gives minimum concrete temperatures at time of placement and as initially maintained as a function of member thickness:

In addition to carefully monitoring the concrete temperature, formwork, reinforcing steel, subbase, subgrade and any other items associated with the placement, the surfaces on which concrete will be placed on should be above 32°F to prevent concrete from freezing at the interface. Once normal-set concrete has been placed, it must be maintained at the above temperature and moist for a specified period of time, usually at least 72 hours, to allow for adequate initial curing. The use of insulating blankets, heated mats, and/or heated enclosures may be necessary. Don’t wait until the last minute to confirm that protective equipment and supplies are on site. ACI 306R contains much more guidance on the types and duration of protective measures that may be necessary for newly-placed concrete.

The handling of field-cured cylinders becomes especially critical during cold weather operations. When used to confirm suitable field strength for formwork removal, post-tensioning, or steel erection, every reasonable effort must be made to ensure these cylinders receive the same temperature and moisture treatment as the concrete they represent.

Mix Design Considerations

It is often worth considering modifying concrete mix designs during the winter. Using higher-strength mixes can lead to early strength gain and thereby allow faster formwork removal. Other suggestions to accomplish this include lower water/cementitious material ratios, adding additional cement, using a non-chloride accelerating admixture, or using a Type III cement (high-early strength).

The addition of calcium chloride has often been used in the past as an accelerating admixture, but caution is advised. Chlorides in concrete can increase the possibility of corrosion in the embedded reinforcing steel and other adverse effects. Many specifications and code documents limit or completely restrict the use of calcium chloride or admixtures containing chlorides.

Some of the common mineral admixtures such as slag, fly ash, or silica fume should also be reviewed in periods of cold weather. There are numerous advantages in using what are now called supplementary cementitious materials, but they can also retard initial strength gain. This phenomenon tends to be more pronounced in cold weather, and an accelerating admixture or other actions may be required if the delayed strength gain would affect finishing or formwork removal.

The ACI also recommends the use of air entrained concrete to minimize damage from freeze-thaw cycles even if the concrete will only be exposed to these cycles during construction.

ACI 306R-16

The latest edition of ACI 306R (2016 edition) has continued some interesting recent changes to cold weather concreting–particularly discouraging the use of field-cured cylinders to evaluate in-place strength and modifying the minimum temperature of the surfaces that fresh concrete comes in contact with. As these changes become accepted into the way we operate, future modifications to standard procedures are likely.